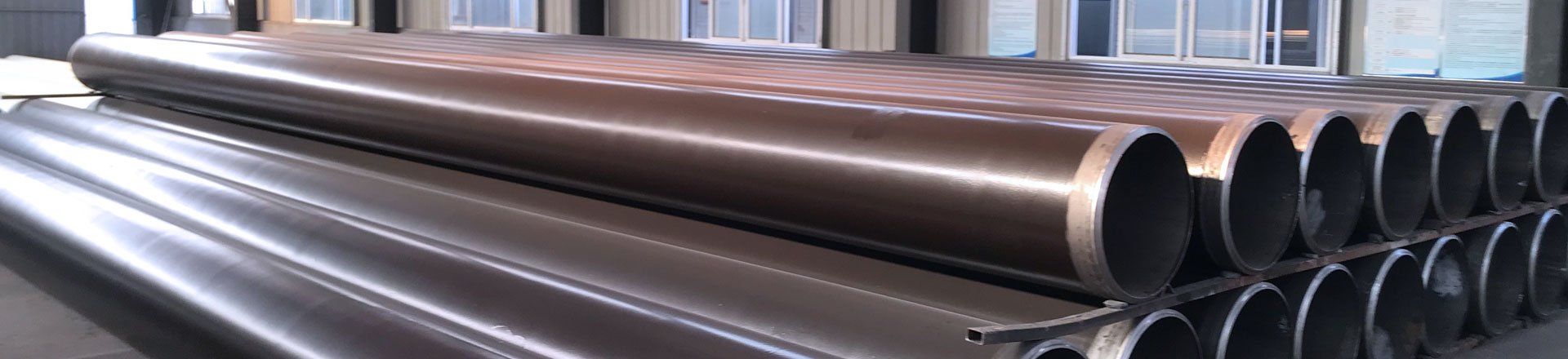

Engineered for Longevity in Harsh Environments

Xinyue Steel produces robust LSAW pipes with advanced anti-corrosion coatings, providing extended service life and superior protection for pipelines operating in corrosive conditions. Our solutions are tailored to meet the specific demands of your project, from external soil and moisture to internal fluid composition.

Our Anti-Corrosion Solutions:

We apply high-performance protective coatings to our base LSAW pipes (manufactured via JCOE, UOE, or T-Welded processes). Key systems include:

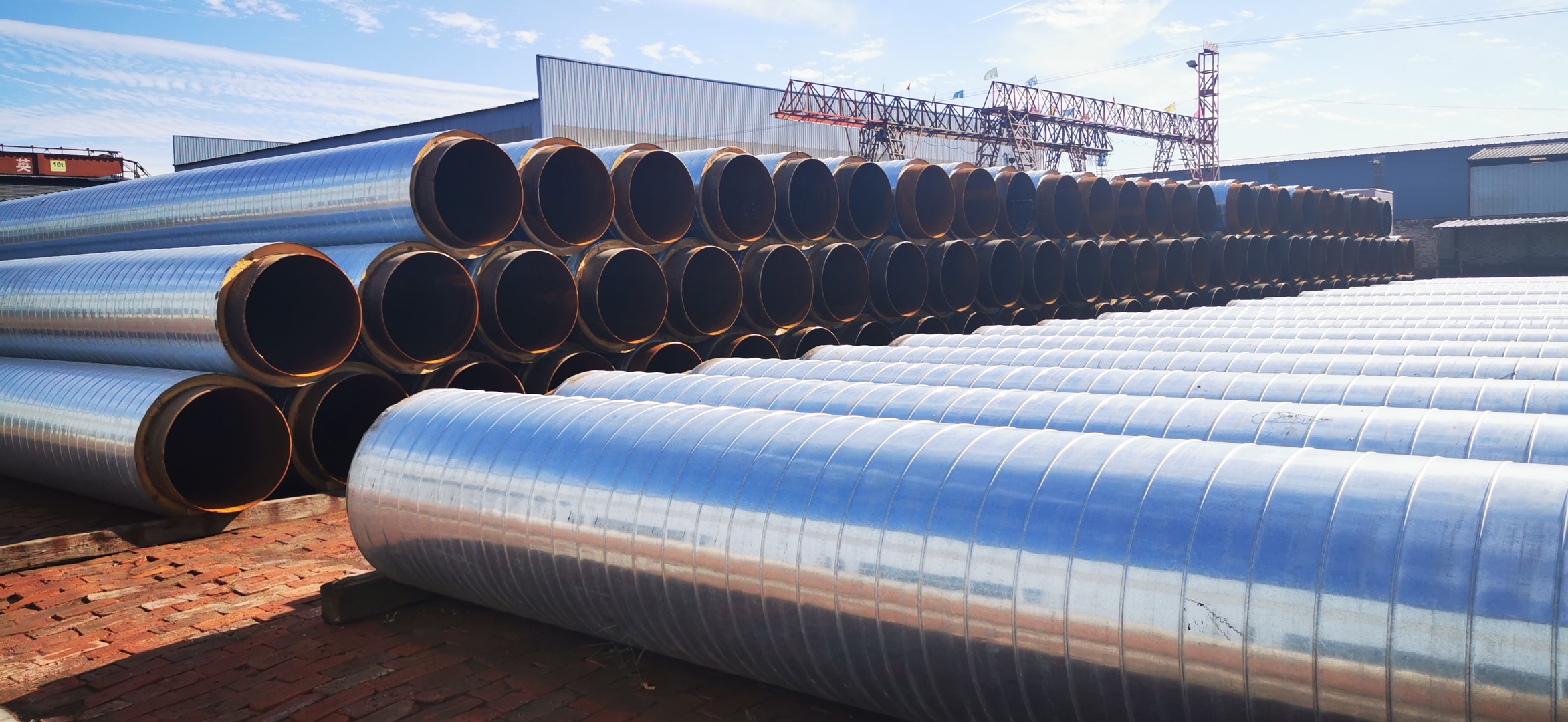

· 3LPE / 3LPP Coating: The industry standard for external protection. A 3-Layer Polyethylene or Polypropylene coating system offering excellent mechanical strength and chemical resistance.

· FBE Coating: Fusion-Bonded Epoxy provides a thin, hard, and durable film with strong adhesion and cathodic disbondment resistance.

· Internal Linings & Coatings: For internal corrosion resistance, we apply epoxy linings, cement mortar, or other solutions based on the transported medium.

· Cathodic Protection Ready: Our coated pipes are designed to work seamlessly with impressed current or sacrificial anode cathodic protection systems for comprehensive defense.

Key Advantages of Our Coated Pipes:

· Extended Service Life: Drastically reduces corrosion, minimizing maintenance and replacement costs.

· Enhanced Reliability: Protects pipeline integrity, preventing leaks and ensuring safe, uninterrupted operation.

· Proven Performance: Coatings are applied under strict quality control to meet international standards for thickness, adhesion, and resistance.

· Customized Solutions: We select the optimal coating system based on your specific environmental and operational requirements.

Our Product Specifications:

· Base Pipe Standards: API 5L, ISO 3183, ASTM A252, etc.

· Coating Standards: ISO 21809-1, CAN/CSA Z245.20, CAN/CSA Z245.21, AWWA C210, C205.

· Steel Grades: From B, X42, X52, X60, X65, X70, up to X80.

· Sizes: All standard LSAW diameters from 16" (406mm) to 64" (1625mm), with wall thicknesses up to 40mm.

· Applications: Ideal for cross-country oil & gas pipelines, water transmission, offshore pipelines, piling in aggressive soils, and chemical effluent lines.

Why Choose Xinyue Steel for Anti-Corrosion Pipes?

Our integrated process—from pipe forming to coating application—ensures a perfectly compatible and high-quality product. We provide a complete corrosion mitigation package, guaranteeing performance and durability.

Contact our experts to specify the right anti-corrosion protection for your project's environment.

.png)

.png)