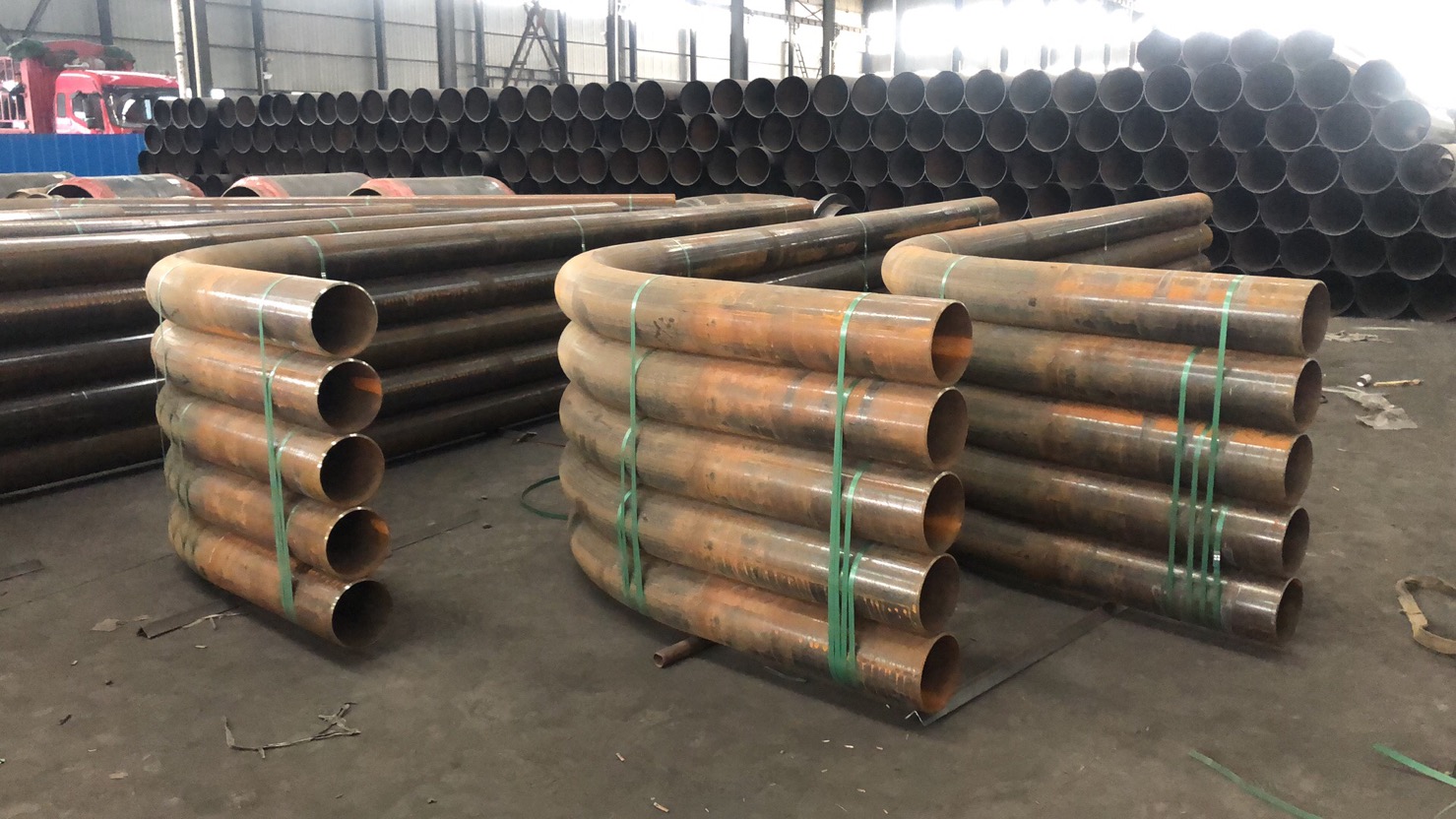

For Efficient Pipeline Routing

Our Bending Capabilities:

We employ advanced CNC-controlled bending methods to achieve precise results:

· Cold Bending: Suitable for most applications, this method bends the pipe at ambient temperature using mechanical force. It is efficient and ideal for larger radius bends.

· Induction Heat Bending (Hot Bending): For tighter radii and more complex bends, the pipe section is precisely heated by induction coils before bending. This allows for severe deformation without compromising the pipe's wall thickness or mechanical properties.

Key Advantages of Our Pipe Bends:

· Enhanced Flow Efficiency: Smooth, continuous bends minimize pressure loss and turbulence compared to welded elbows.

· Increased Structural Integrity: Fewer field welds reduce potential leak points and weakenings in the pipeline.

· Precision Geometry: Our computer-controlled process guarantees accurate bend angles and radii, ensuring perfect fit-up during installation.

· Material Preservation: Advanced techniques, especially heat bending, are designed to control wall thinning and ovality, preserving the pipe's pressure-containing capability.

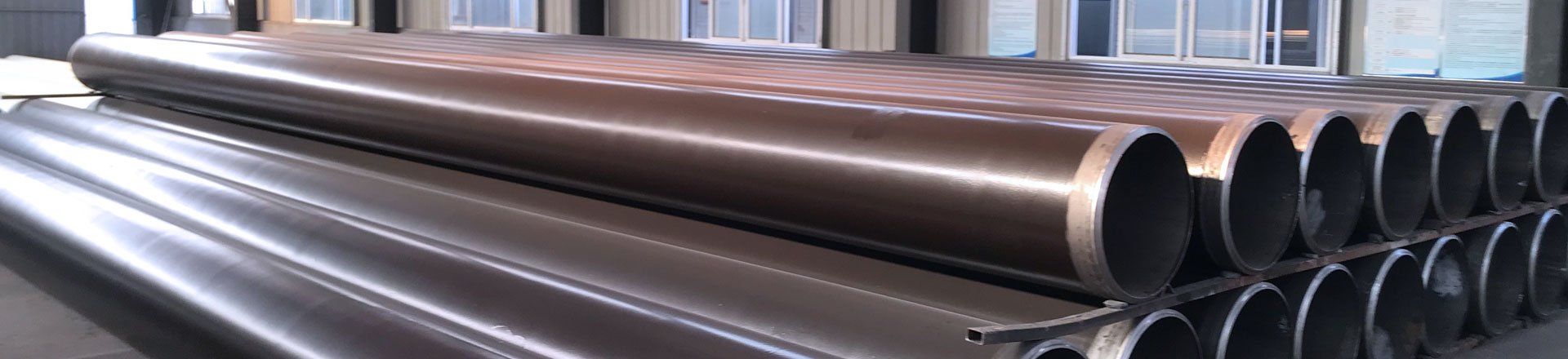

Our Product Specifications:

· Base Pipe Standards: API 5L, ASTM A53, ASTM A106, ASTM A333.

· Bending Standards: ISO 15590-1, ASME B16.49, or custom project specifications.

· Steel Grades: GR.B, X42, X52, X56, X60, X65, X70.

· Sizes: Bent from LSAW pipes with diameters from 16" (406mm) to 48" (1219mm).

· Wall Thickness: Up to 40mm (1.575”).

· Bend Radius: Customizable from 3D to 10D and beyond.

· Applications: Critical for directional changes in oil & gas transmission pipelines, water pipelines, plant piping systems, and structural frameworks.

Why Choose Xinyue Steel for Pipe Bends?

We combine our expertise in high-grade LSAW pipe production with state-of-the-art bending technology. This ensures a reliable, ready-to-install component that meets the stringent demands of your pipeline project, from conception to completion.

Contact us with your bend requirements for a precise quote and technical consultation.

.png)

.png)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)