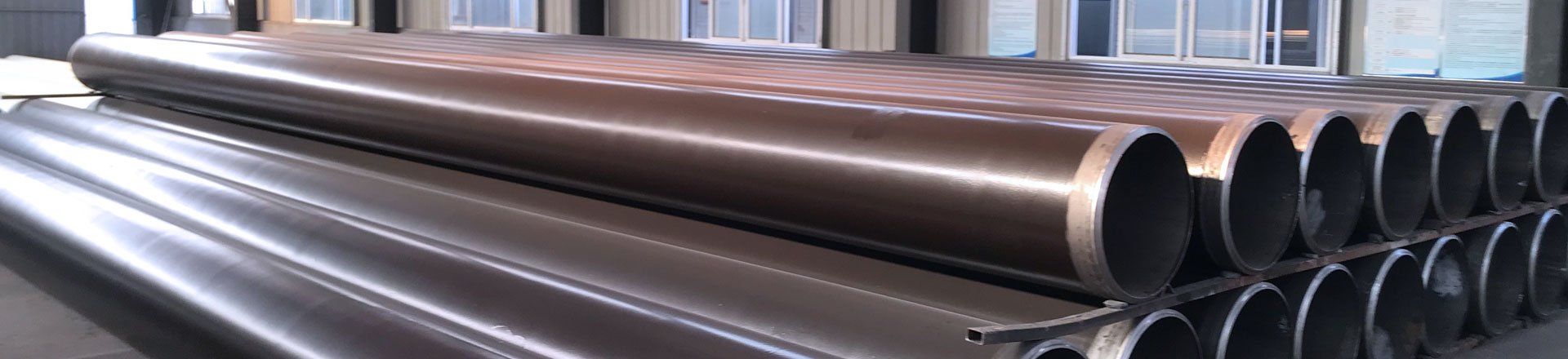

The UOE Manufacturing Process: High-Volume Excellence for Pipeline & Structural Applications

Xinyue Steel leverages the industry-proven UOE forming process to produce premium Longitudinal Submerged Arc Welded (LSAW) pipes. This method is renowned for its high production efficiency and exceptional consistency, making it the preferred choice for major pipeline and structural projects.

What is the UOE Process?

UOE is a highly efficient cold-forming method where premium steel plates are shaped through three primary steps:

· U (U-ing): The steel plate is first pressed into a "U" shape using a large U-press.

· O (O-ing): The U-shaped plate is then pressed into a perfect circular "O" shape in a powerful O-press, with the edges ready for welding.

· E (Expanding): After welding, the entire pipe body is mechanically expanded. This critical step sets the final diameter, eliminates stress, improves geometric accuracy, and optimizes mechanical properties.

Key Advantages of Our UOE LSAW Pipes:

· Unmatched Consistency: Ideal for high-volume projects requiring uniform dimensions and performance across thousands of pipes.

· Superior Roundness and Straightness: Excellent for pipeline laying and structural piling where precise fit is paramount.

· High Production Capacity: The process is optimized for efficient, large-scale manufacturing.

· Exceptional Weld Integrity: Submerged Arc Welding (SAW) under strict controls guarantees a flawless, high-strength seam.

Our Product Specifications:

· Standards: API 5L, ISO 3183, EN 10219, DNV, and other international standards.

· Grades: From API 5L B, X42, X52, X60, X65, X70, up to X80 and higher.

· Outside Diameter: 18" (457mm) to 64" (1625mm).

· Wall Thickness: Typically up to 40mm (1.575”).

· Applications: Primarily used for long-distance oil and gas transmission pipelines, offshore pipelines, and large-diameter structural columns.

Why Choose Xinyue Steel for UOE Pipes?

Our advanced UOE production line and rigorous quality management system ensure that every pipe delivers maximum reliability and value for your most critical energy and infrastructure projects.

.png)

.png)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)