Robust Solutions for Piling and Construction

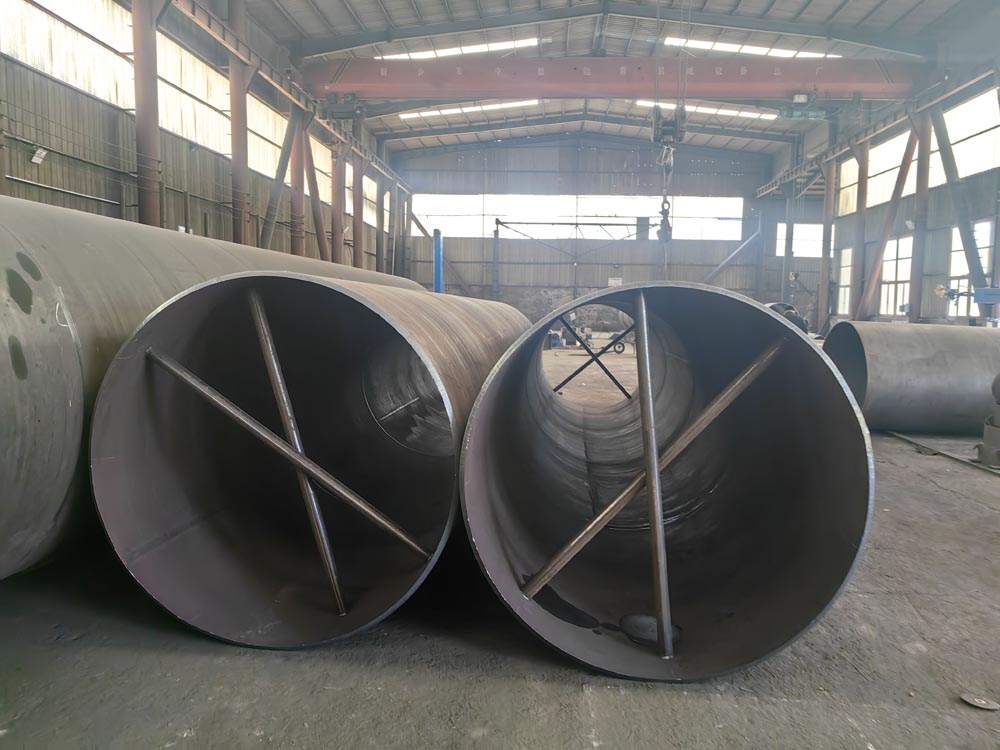

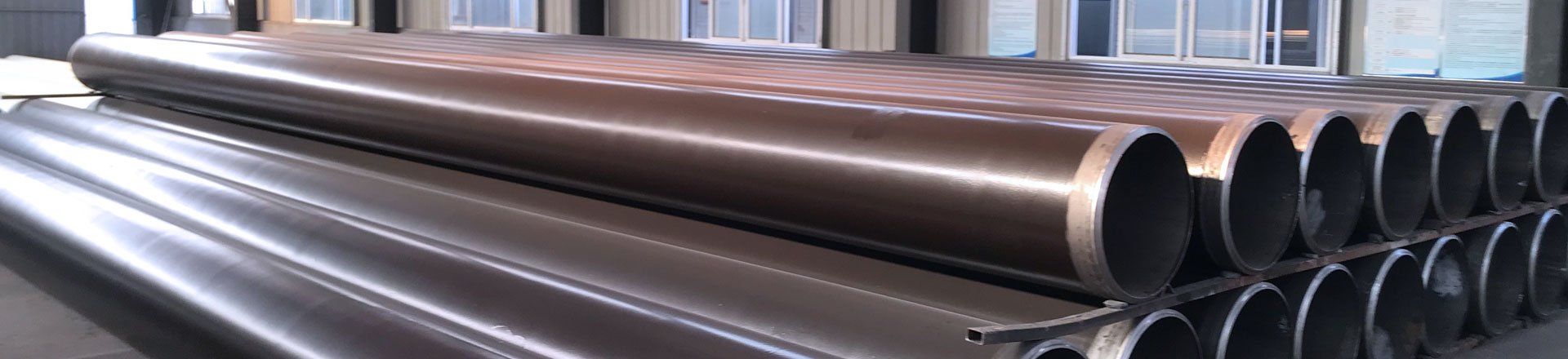

Xinyue Steel manufactures high-strength T-Welded LSAW pipes, a specialized variant designed for superior performance in demanding structural applications. This process focuses on creating a single, robust longitudinal seam to produce pipes with exceptional axial load-bearing capacity.

What is the T-Welded LSAW Process?

The "T" refers to the shape of the weld preparation. In this efficient and cost-effective process:

· A single steel plate is cold-formed into a cylindrical shape.

· The prepared edges are brought together to form a precise "T" groove preparation.

· The longitudinal seam is then welded using the reliable Submerged Arc Welding (SAW) method, both internally and externally, creating a deep penetration weld with high integrity.

Key Advantages of Our T-Welded LSAW Pipes:

· Excellent Load-Bearing Strength: The weld design offers outstanding resistance to axial compression and bending stresses.

· Cost-Effectiveness: An efficient manufacturing process ideal for large-diameter, thick-walled pipes.

· High Structural Integrity: The consistent, full-penetration weld ensures reliability for foundational support.

· Simplified Production: Optimized for producing pipes that prioritize structural strength over complex forming.

Our Product Specifications:

· Standards: API 5L, ASTM A252, EN 10219, and other international piling specifications.

· Grades: Commonly GR.B, X42, X52, up to X70, and ASTM A252 GR.2/GR.3.

· Outside Diameter: 16" (406mm) to 64" (1625mm) and larger.

· Wall Thickness: Typically from 8mm up to 40mm (1.575”) and thicker.

· Applications: Primarily used for foundation piling (pipe piles), retaining walls, and structural columns in construction, bridges, and port infrastructure.

Why Choose Xinyue Steel for T-Welded Pipes?

Our expertise in structural steel manufacturing ensures that our T-Welded LSAW pipes provide the dependable strength and value required for your most critical construction and civil engineering projects.

.png)

.png)

(1).JPG)