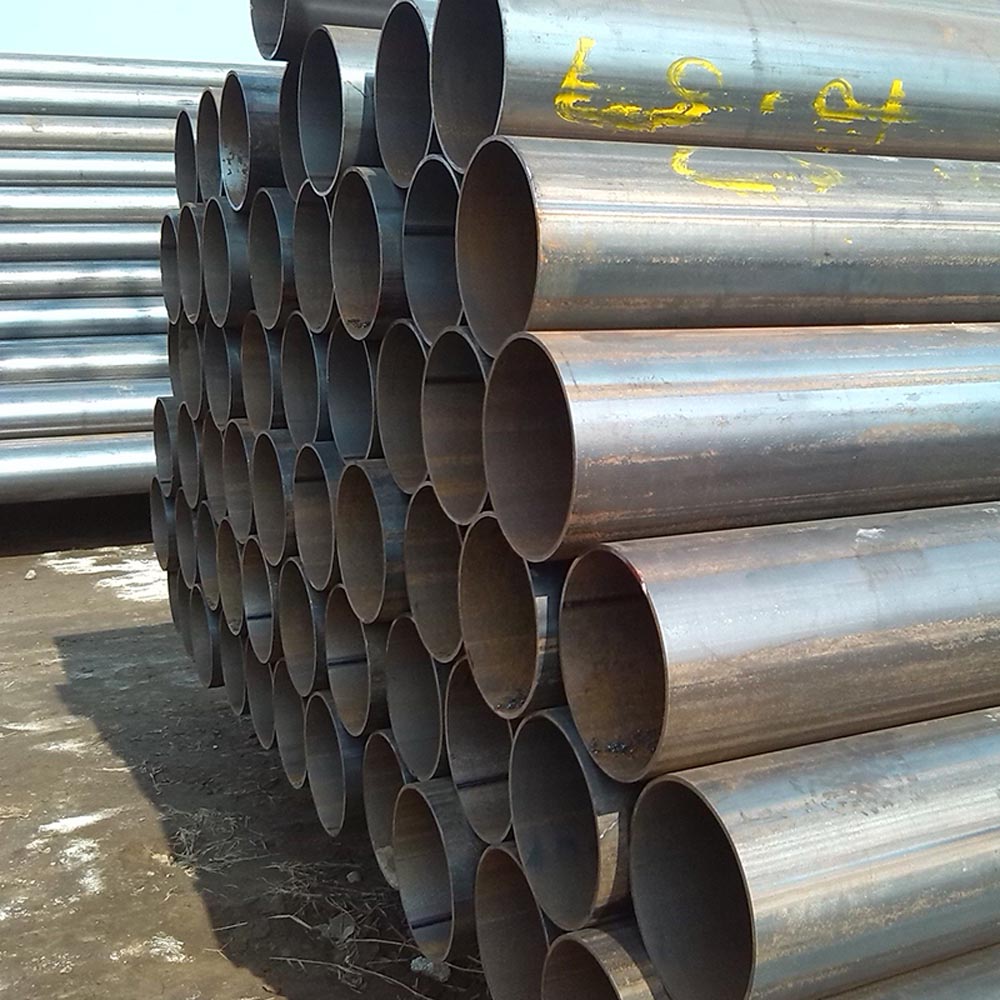

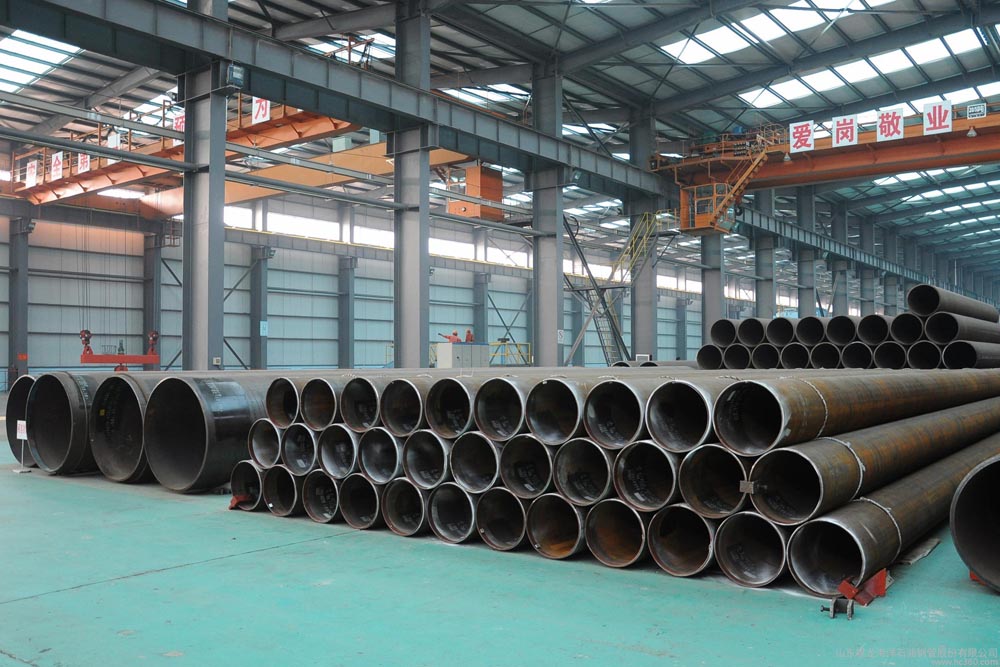

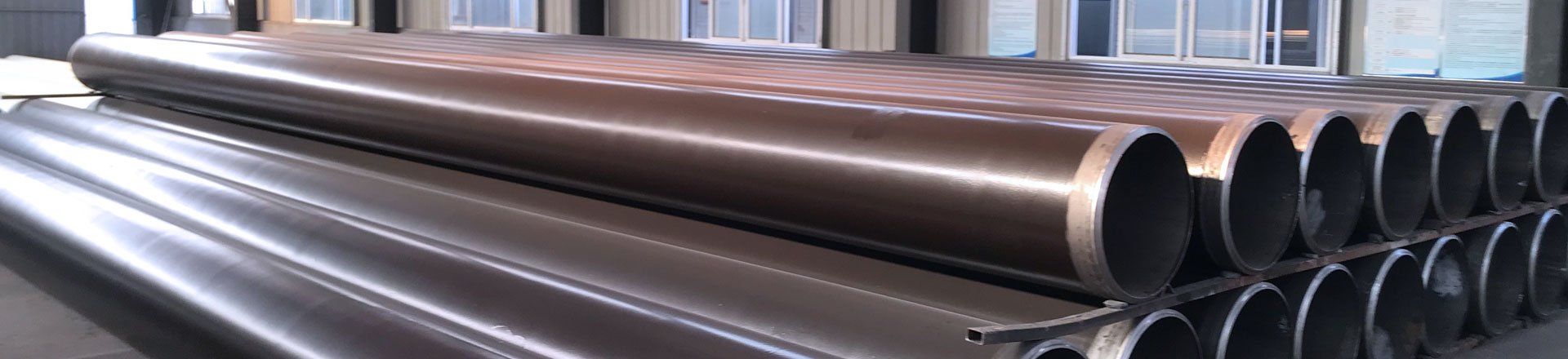

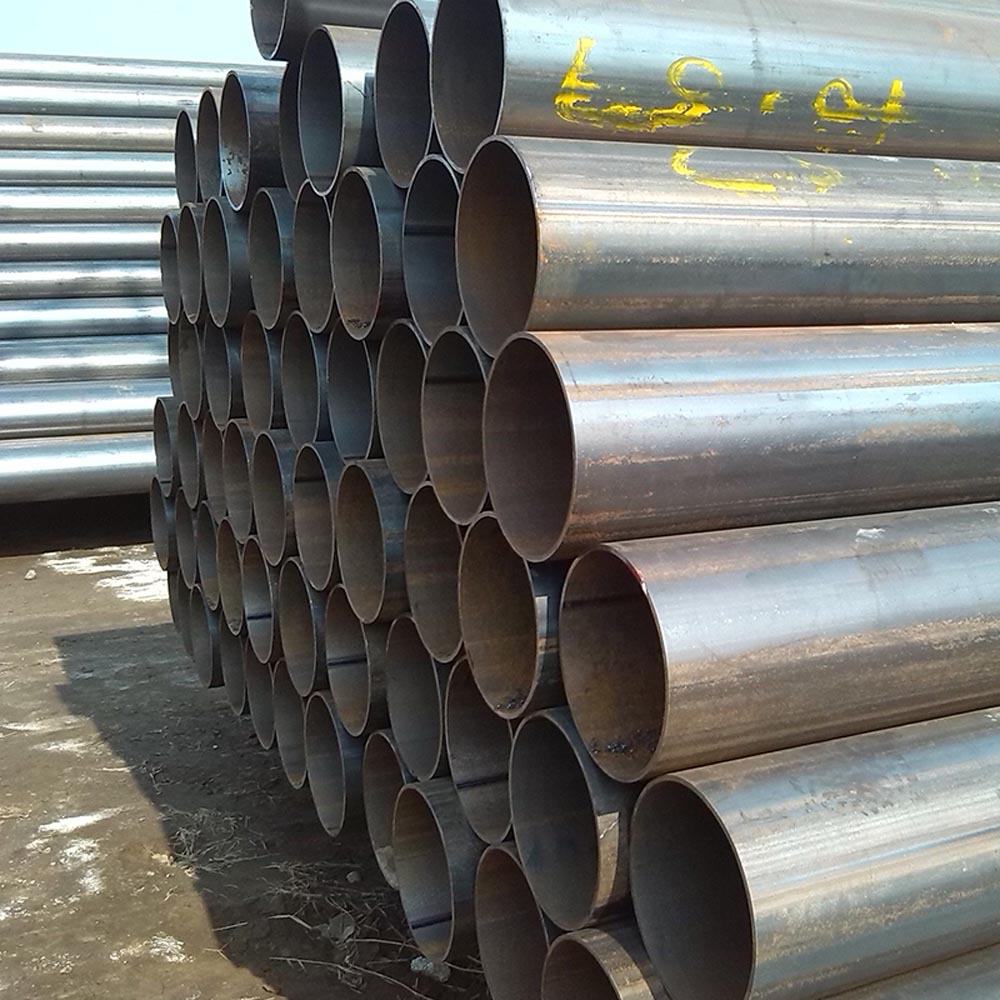

Precision Engineering for Superior LSAW Pipes

At Xinyue Steel, we employ the advanced JCOE forming process to manufacture high-quality Longitudinal Submerged Arc Welded (LSAW) steel pipes. This method ensures exceptional structural integrity, dimensional accuracy, and performance for critical applications worldwide.

What is the JCOE Process?

JCOE is a sophisticated cold-forming technique. Steel plates are precisely shaped through a series of steps:

· J (Joggle-End Pressing): The plate ends are pre-formed to ensure a perfect fit for welding.

· C (Crimping): The long edges of the plate are curved to the required radius.

· O (O-forming): The plate is gradually pressed into a circular "O" shape through multiple steps.

· E (Expanding): The welded pipe is mechanically expanded. This crucial step optimizes dimensional accuracy, relieves internal stresses, and improves overall pipe strength and roundness.

Key Advantages of Our JCOE LSAW Pipes:

· Superior Mechanical Properties: The controlled forming and expanding process enhances yield strength and tolerances.

· Excellent Dimensional Accuracy: Ideal for projects requiring precise fit and alignment.

· Wide Size Range: Capable of producing larger diameters and thicker walls compared to other methods.

· High-Quality Welds: Submerged Arc Welding (SAW) ensures a robust, consistent, and reliable weld seam.

Our Product Specifications:

· Standards: API 5L, EN 10219, ASTM A252, ASTM A500, and more.

· Grades: From GR.A, B, X42 to X80 and higher grades.

· Outside Diameter: 16" (406mm) to 64" (1625mm) and beyond.

· Wall Thickness: Up to 40mm (1.575”).

· Applications: Ideal for oil and gas transmission pipelines, piling, foundation piles, and structural columns in construction and infrastructure projects.

Why Choose Xinyue Steel for Your LSAW Needs?

With our expertise in the JCOE process and stringent quality control, we deliver LSAW pipes that meet the most demanding project specifications. Our commitment is to provide reliable, high-performance piping solutions built to last.

.png)

.png)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)